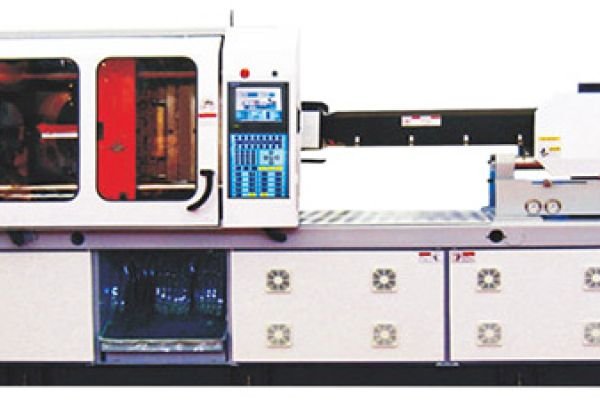

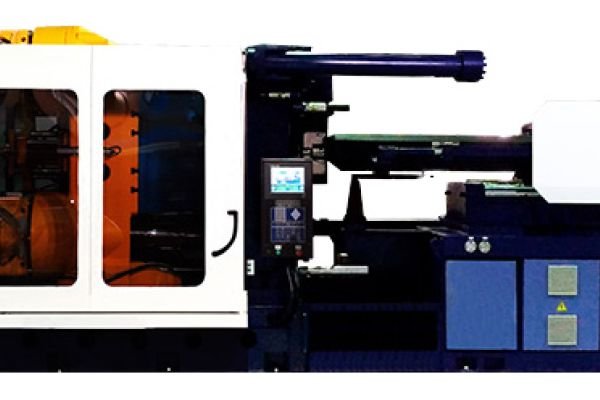

Horizontal Closure Injection Molding Machines

DSM’s Horizontal Closing Injection Molding Machines! State-of-the-art technology: Ensures high precision, reliability, efficiency, and speed in the plastic injection process. Various models and configurations: Meeting the most varied production needs in different industrial segments. Hydraulic and servo hydraulic versions: Flexibility to choose the optimal technology for your application. Double Plate Plastic Injection Molding Machines: Greater stability and precision for high quality parts. Special Injection Molding Machines: Customized solutions to meet your specific needs. One, two or three extruders: Options for different production volumes and part complexity. Precise temperature and pressure control: Ensures high quality and consistent parts. Efficient laminating system: Minimizes cycle time and optimizes production. Robust injection unit: Ensures high pressure and precision in the injection of the material. Robust and durable structure: Designed to operate in demanding environments and with high reliability. Enhanced Safety: Advanced safety devices to ensure the protection of the operator and the working environment. Specialized technical support: Count on an experienced team to assist you in choosing, installing, operating and maintaining the machines. Request a quote today and find out how DSM’s Horizontal Closing Injection Molding Machines can boost your business, optimize your production processes, increase your profitability, improve the quality of your products, take you to a new level of efficiency, competitiveness and help you achieve your goals!